Suspended permanent magnet iron remover, the internal use of high-strength permanent magnets to form a composite magnetic system, double magnetic pole structure, large magnetic pole adsorption area, can automatically absorb ferromagnetic impurities from moving materials. The suspended permanent magnet iron remover of this machine can be used in conjunction with various types of belt conveyors, vibrating feeders or chutes, and can remove various ferromagnetic substances from moving materials.

scope of application

It is suitable for removing iron from non-magnetic materials on belt conveyors, vibrating feeders, and feeding chutes.

Advantages

1. The combined magnetic system of high-strength permanent magnets such as Ru-Fe-B is used, which has high magnetic field strength and strong suction.

2. It is easy to install, easy to use, reliable in operation and easy to maintain.

3. Compared with the electromagnetic iron remover, it has the following advantages: the required upper installation space is small, the operating cost is low, the operation is simple, the structure is stable, there are few faults, and it can also avoid shutdown accidents caused by power failures.

4. The cost is relatively low, and it can solve the separation of magnetic materials and non-magnetic materials to a large extent.

Product description

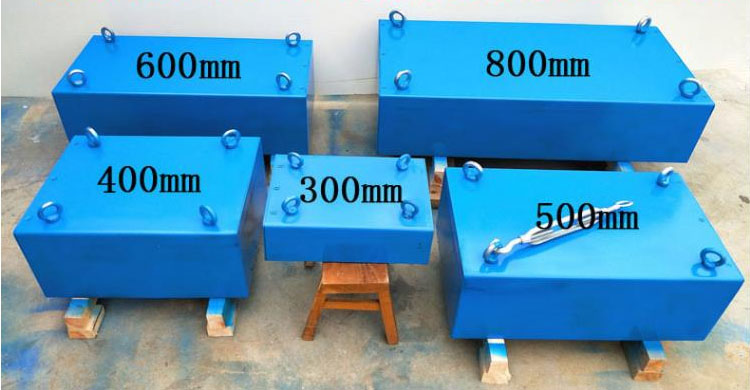

Product Dimensions

working principle

Permanent magnetic suspension type iron remover uses high-performance permanent magnetic material NdFeB inside, which can form a strong suction force in the magnetic circuit. It is a new type of lifting tool that is safe, energy-saving and efficient.

Iron removal method: When the permanent magnet material has a lot of iron adsorption, it can be removed manually with a non-magnetic scraper or removed with gloves. It is suitable for continuous work and iron removal process with less iron content.

Description of installation location

The ideal installation position of the hanging iron remover is directly above the parabola where the material departs from the conveyor belt, which is the installation position represented by 0.

If a suitable parabolic path can be formed, the zero installation can maximize the full capacity of the iron separator. Because the processed material moves directly to the surface of the magnet, its own momentum helps the magnetic field to capture the miscellaneous iron. When the belt speed is slow, the falling path of the material is close to the vertical direction, and the position of the magnet must be moved backward so as to be closer to the pulley. For low belt speeds, it may be necessary to install non-magnetic pulleys.

CHINESE

CHINESE Baoding Lianchi Tengbo Machinery Equipment Factory

Baoding Lianchi Tengbo Machinery Equipment Factory